FCCS07 FeCuCoSn Pre Alloyed Metal Powde bakeng sa Lisebelisoa tsa Taemane tsa Boleng bo Hare ho isa ho Bo phahameng

FCCS07 FeCuCoSn Pre Alloyed Metal Powde bakeng sa Lisebelisoa tsa Taemane tsa Boleng bo Hare ho isa ho Bo phahameng

1. Pele ho alloyed Powder ke eng

Li-powders tse kentsoeng pele li thata ho feta, ha li hatellehe haholo, ka hona, li hloka hore ho be le meroalo e phahameng haholo ho hlahisa li-compact tse ngata.Leha ho le joalo, ba khona ho hlahisa lisebelisoa tse matla tsa sintered.Pre-alloying e boetse e sebelisoa ha tlhahiso ea thepa e homogeneous ho tloha elemental powders e hloka mocheso o phahameng haholo le linako tse telele tsa sintering.Mehlala e metle ka ho fetisisa ke litšepe tse sa hloekang, tseo likahare tsa chromium le nickel li lokelang ho lokisoa esale pele ho lumella tlhahiso ea moruo ka phofo ea metallurgy.

2. Mekhahlelo ea FCCS07

| Ntho e ka Sehloohong | Fe, Cu, Co, Sn |

| Theorytical Density | 7.84g/cm³ | |

| Sintering Mocheso | 790 ℃ | |

| Matla a Kobehang | 1500Mpa | |

| Ho thatafala | 105-110HRB |

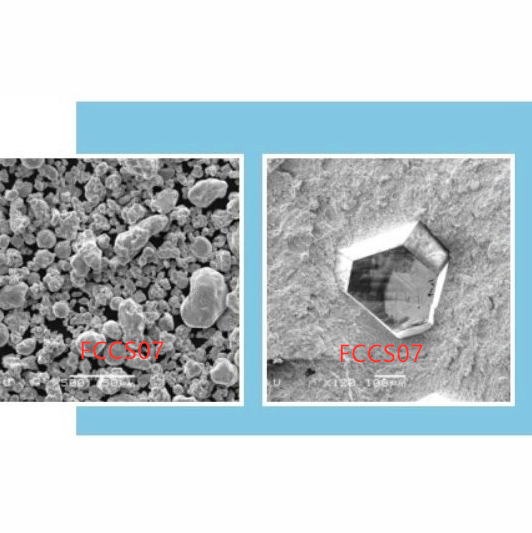

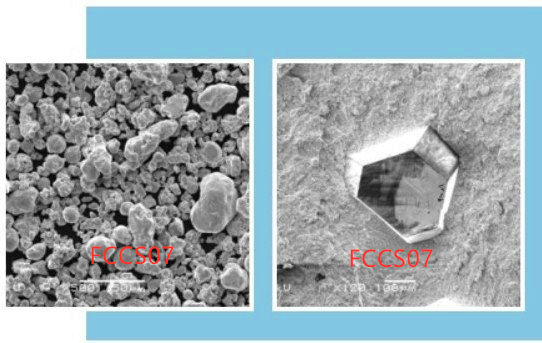

3. FCCS07 Sebopeho sa Phofo se Alloed Pele

- Phofo e na le bokhoni bo botle ba ho kolobisa daemane le granulating e kholo ea mechine ho li-powders tse ling tsa tšepe, e ka thusa lihlahisoa ho finyella bohlokoa bo boholo ka lebelo le bophelo.

- E sebelisoa ho lehare la daemane la granite la boleng bo bohareng ho isa bo holimo, lehare la taemane la ceramic, terata ea daemane le likotoana tsa mantlha tsa daemane.

4. Taelo ea Tšebeliso bakeng sa Ceramic Cutting Blade

- Phofo ea tšepe

- 30-50% FCCS07

- + 25-35% Cu

- + 3-6% Sn

- + 2-5% Ni

- + 7-10% CUCS

- + Fe bakeng sa tekanyo

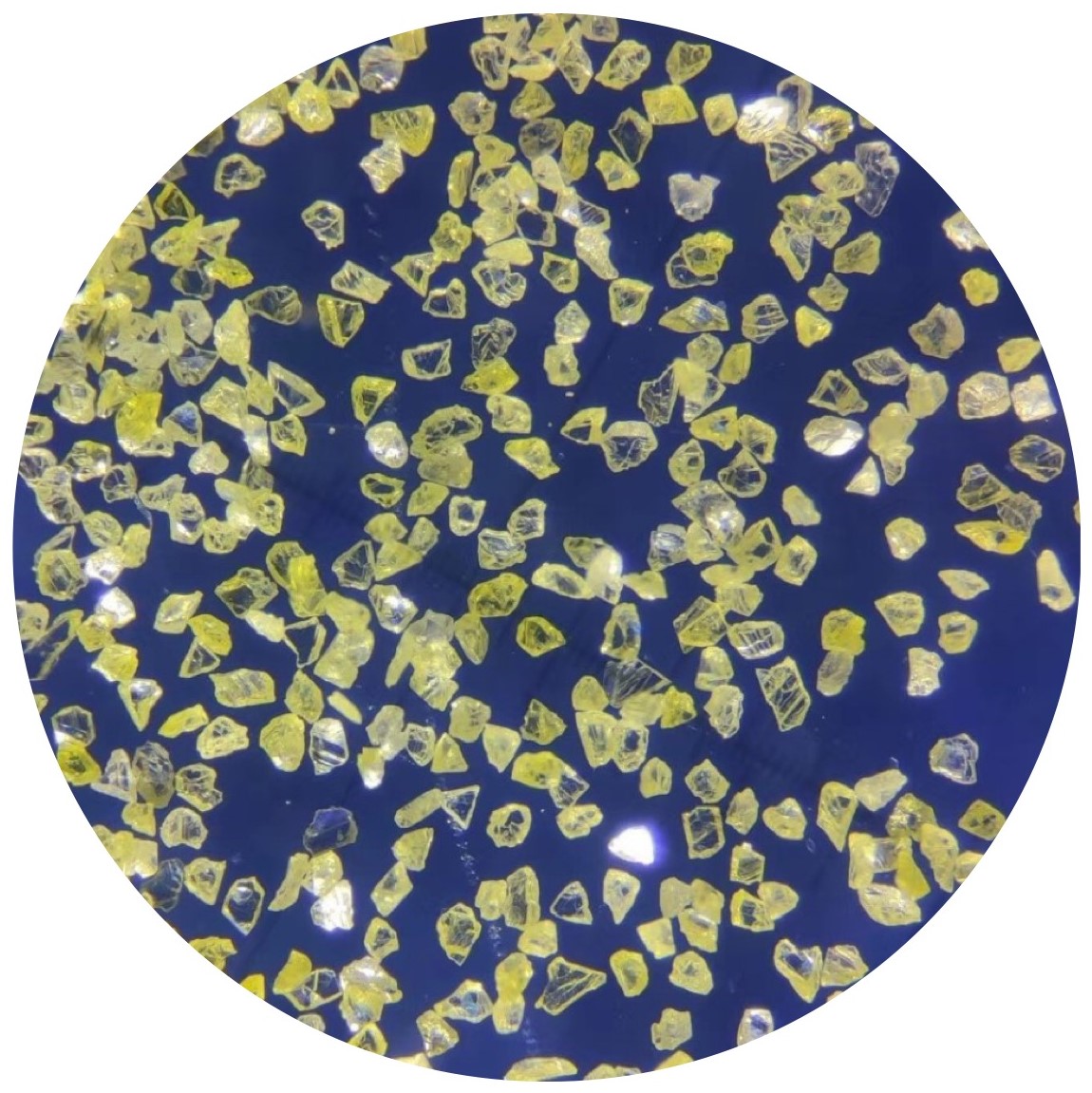

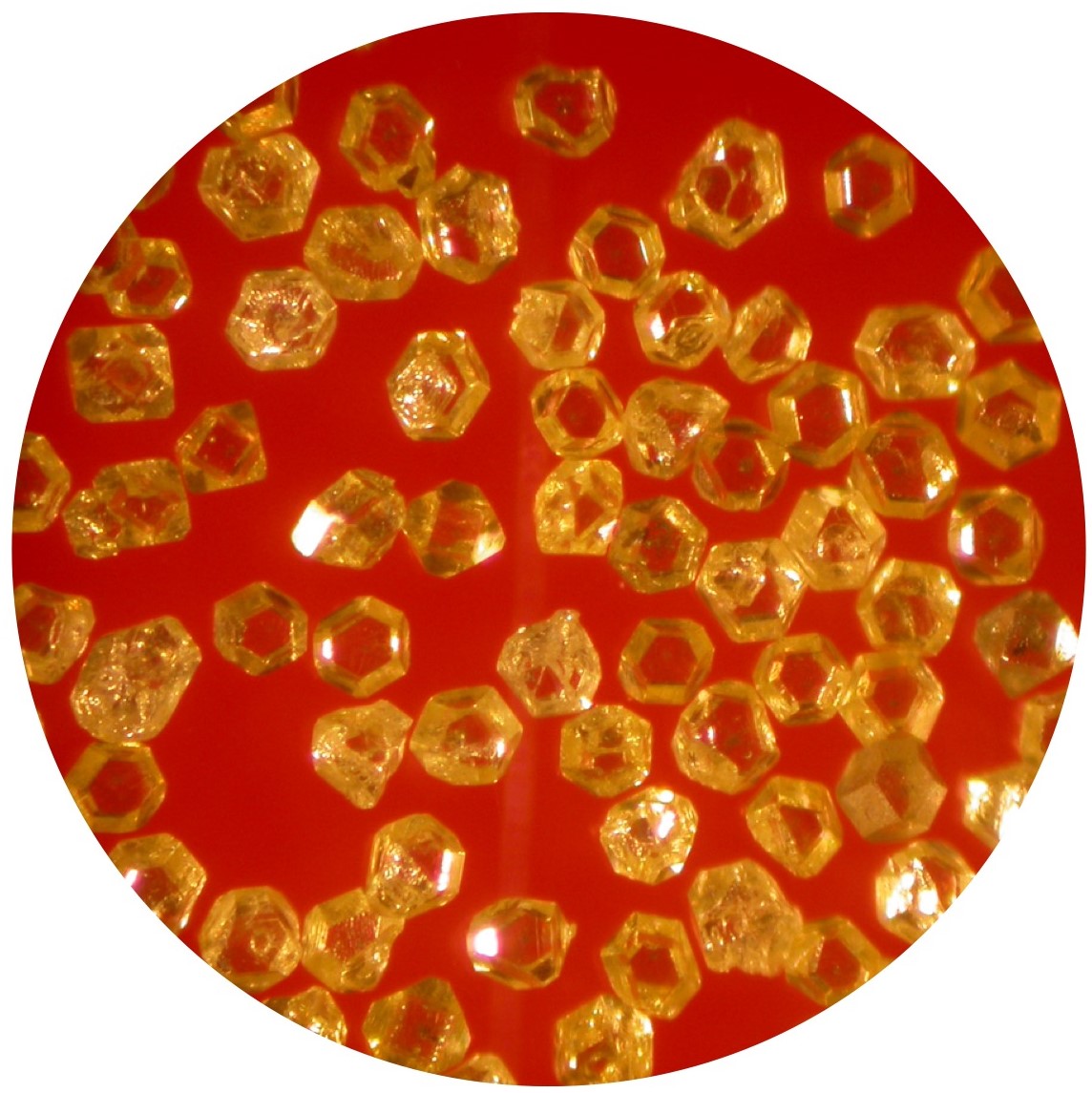

B. Diamond bakeng sa Ceramic e Omileng ea ho Seha

- 50/60 @ 30%

- 60/70 @ 40%

- 70/80 @30%

- Mahlohonolo a Taemane @ 13-15%

C. Taemane bakeng sa Ceramic ea ho Seha Metsi

- 50/60 @ 60%

- 60/70 @ 40%

- Mahlohonolo a Taemane @ 10-12%

D. Sintering Mocheso 830-850℃