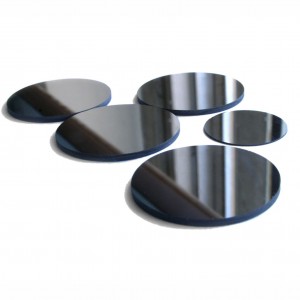

Polycrystalline Cubic Boron Nitride (PCBN) bakeng sa Lisebelisoa tsa Machining

Li-composites tsa PCBN li hlahisoa ka sintering micron CBN phofo e nang le ceramic e fapaneng, e le ho hlahisa lisebelisoa tse thata haholo le tse tsitsitseng ka mocheso Boholo ba lisebelisoa tsa PCBN li hokahane ka botlalo le karoloana e samente ea carbide.CBN ke thepa ea bobeli e thata ka ho fetisisa e tsejoang ka mor'a taemane ea maiketsetso, empa e na le thepa e phahameng ea mocheso le lik'hemik'hale.E sebelisoa haholo ho seha le ho sebetsana le boima bo phahameng kapa ho thata ho sebetsana le lisebelisoa tse kenyelletsang tšepe e thata, e bohlooho le tšepe e matla e phahameng, tšepe e phahameng ea lebelo, alloy ea tšepe e timang tšepe, lisebelisoa tsa tšepe tsa sintering, joalo-joalo.

| Khouto # | Diameter (mm) | Lera la daemane (mm) | Bophahamo(mm) | Abrasive ratio | Sebopeho | Kopo |

| HC1303 | 13.5 | 0.8-1.0 | 3.2 | > 10000 |

CBN layer le Wc-co substrate High CBN content 2. Ho hanyetsa ho apara ho phahameng 3. Matla a matle a ho phatloha 4.Ho tsitsisa lik'hemik'hale tse ntle | 1. Nepahetseng dimension2.Grey cast iron3.Matla a Metal4.Ho hanyetsa mocheso 5. Tlosa motsoako 6. Lisebelisoa tšepe & die tšepe |

| HCF1304 | 13.5 | 0.8-1.0 | 4.5 | |||

| HC3201 | 32.0 | 0.8-1.0 | 1.6 | |||

| HC3202 | 32.0 | 0.8-1.0 | 2.4 | |||

| HC3203 | 32.0 | 0.8-1.0 | 3.2 | |||

| LC1303 | 13.5 | 0.8-1.0 | 3.2 | >3000-4000 |

CBN layer le Wc-co substrate 2. Likahare tse tlase tsa CBN 3. Karolelano e phahameng ea ho apara 4. Matla a matle a ho thibela ho phatloha |

likarolo tsa metallurgy |

| LC1304 | 13.5 | 0.8-1.0 | 4.0 | |||

| LC3201 | 32.0 | 0.8-1.0 | 1.6 | |||

| LC3202 | 32.0 | 0.8-1.0 | 2.4 | |||

| LC3203 | 32.0 | 0.6-0.8 | 3.2 | |||

| HB0903 | 9.55 | 3.18 | 3.18 | > 5000 |

|

|

| HB1204 | 12.7 | 4.76 | 4.76 | |||

| HB1608 | 15.85 | 8.0 | 8.0 | |||

| HB2008 | 20.0 | 8.0 | 8.0 |