Polycrystalline Diamond Compact PDC Cutters Bakeng sa ho Cheka Oli le Khase

Polycrystalline Diamond Compact PDC Cutters Bakeng sa ho Cheka Oli le Khase

1.Lintho tsa PDC ke eng?

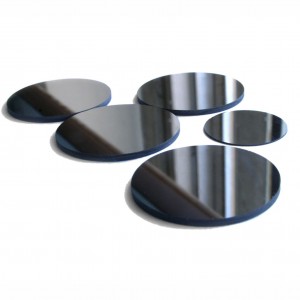

PDC- Polycrystalline diamond compact e entsoe ka polycrystalline diamond layer le tungsten carbide substrate, polycrystalline daemane layer e na le thata e phahameng haholo le khanyetso ea abrasion athe substrate ea tungsten carbide e ka ntlafatsa haholo ts'ebetso le bokhoni ba weld ba motsoako kaofela, manyolo a daemane a polycrystalline ke e sebelisitse peterole ea liliba tsa oli, tlhahlobo ea jeoloji, merafo ea mashala le indasteri ea mechini.

Polycrystalline diamond manyolo ka litlama (PDC) sehang sehang bakeng sa ho cheka ho loketseng bakeng sa bonolo ho ea ka thata geological terrane ho ea ka tlhokahalo ea bareki re ka fana ka polycrystalline taemane compact e nang le claw mehaho le mefuta ea chamfer hore na ho sila le ho bentsa, re ka fana ka PDC cutters ka sebōpeho se khethehileng ka taelo ea bareki.

GAS Series PDC cutter bakeng sa li-drill tsa peterole le khase e na le ts'usumetso e matla le tekanyo ea ho apara, bophelo bo bolelele ba ts'ebeletso le ts'ebetso e phahameng ea ho cheka tlas'a tikoloho e matsutla.e loketseng bakeng sa popeho ya mafika a bonolo le a mahareng.

2. Tlhaloso ea letoto la GAS PDC cutter

| Khouto # | Diameter (mm) | Bophahamo (mm) | Taemane Tafole |

Charmfer | Wear Ratio | Tšusumetso Khanyetso |

| GAS1308 | 13.44±0.05 | 8.0±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >1600 |

| GAS1313 | 13.33±0.05 | 13.00±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >1600 |

| GAS1608 | 16.0±0.05 | 8.0±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >1800 |

| GAS1613 | 16.0±0.05 | 13.00±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >1600 |

| GAS1908 | 19.0±0.05 | 8.0±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >2000 |

| GAS1913 | 19.0±0.05 | 13.00±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >2000 |

| GAS1916 | 19.0±0.05 | 16.0±0.1 | 1.8~2.0 | 0.41±0.05 | >40 | >2000 |

3. Sebopeho sa GAS PDC Cutter

1) Ka tšobotsi ea ts'ebetso e phahameng ea ts'ebetso, bokaholimo bo boreleli

2) Mekhoa e tsoetseng pele le taolo e thata ea ts'ebetso

3) Nako e telele ea bophelo le ts'ebetso e tsitsitseng

4) Theko ea tlhōlisano le boleng bo phahameng

4. Other PDC Cutter Shape